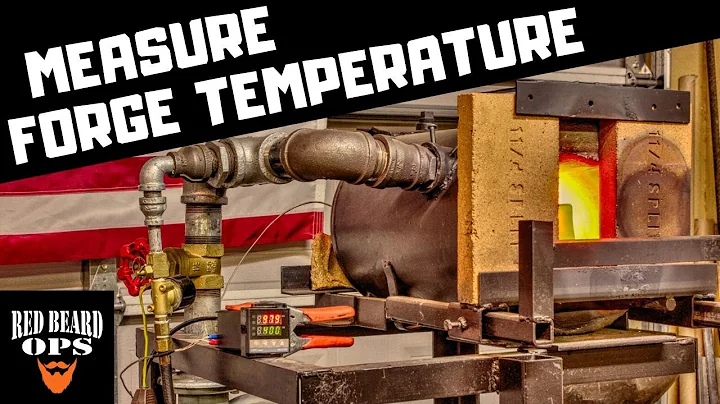

How hot does a small forge get?

The maximum temperature of an atmospheric forge is 2,400 degrees Fahrenheit, reminds Heinz Glaser of Hypona Horse Care Products. “It makes no difference how many burners you have in your forge,” he says.

Hot forging of steel: The forging temperatures are above the recrystallization temperature, and are typically between 950°C–1250°C. Usually, one experiences good formability (i.e., filling of die-cavity in the context of forging), low forming forces, and an almost uniform tensile strength of the work-piece. b.

The combustion temperature of propane is 1,967 degrees F for combustion with air and 2,526 degrees for combustion with pure oxygen (The Engineering ToolBox). Typical forge welding temperatures for a propane forge are accepted as 2,300 degrees F, and common forging can be accomplished at a lower temperature.

A: This forge can reach 2300 degrees which is hot enough to weld; but keep in mind the materi…

The forging process involved molding the knife at a critically high heat level (typically 900 - 2,000 degrees Fahrenheit) to improve its hardness.

Charcoal is considered the least desirable fuel when blacksmithing. While readily available, charcoal may not even reach the necessary temperature to soften iron and steel without a lot of fuel and constant airflow. You can burn through a lot of charcoal quickly and still not achieve the proper temperatures.

Avoid Overheating

When your temperature goes above 1200° C, your steel or low allow metals are up for being damaged. The mechanical properties of your metals become subject to deterioration when heat treatment comes before the forging process.

Blacksmiths cook the coal until most of the impurities are burned off. The result is co*ke, a fuel that is almost entirely carbon allowing us to reach temperature of 3,000 to 4,000 degrees Fahrenheit at the core of the fire! Fire this hot can quickly get the metal up to welding temperatures at about 2,500 degrees.

Most aluminum alloys come up to temp at 800 degrees Fahrenheit. In contrast, steel needs to come up to temp at about 2000 degrees Fahrenheit.

During a wildfire or structure fire, propane tanks are designed to vent so they don't burst or explode. The vented fuel will catch fire if near an ignition source as would be the case in a fire.

What is the lowest temperature you can use propane?

A propane tank cold temperature limit is -44 degrees Fahrenheit — at that point, propane turns from a gas to a liquid. Propane can only heat your home when it's in a gaseous state, not when it's a liquid.

The burners can run efficiently across a pressure range of 3- 20 PSI.

Wood doesn't burn hot enough to work well for this. Ideally you want the following: Insulation bricks, ceramic or the like. A blower or bellows.

As you prepare the fuel for your forge, consider the amount of surface area of the wood. A large chunk of wood does not have as much exposure to oxygen as the same piece will when it is split smaller. The more surface area you have, the faster your wood will become charcoal and make a hot fire.

Your forge should be heated to a temperature between 1500 and 2000°F, which is the usual range for Damascus steel. Then take the following steps: Put the assembled billet in the forge to be heated. Heat the billet until it becomes bright red.

Why Is Stainless Steel Good for Forging? Stainless steel is one of the best types of steel for forging. This is because stainless steel reacts very well in the forging process. Its best qualities, particularly its strength and corrosion resistance, are enhanced by the forging process.

For the higher-alloyed tool steels processed over 2000°F (1095°C), the quench rate from about 1800°F (980°C) to below 1200°F (650°C) is critical for optimum heat-treat response and material toughness.

Pure iron can be welded when nearly white hot; between 2,500 °F (1,400 °C) and 2,700 °F (1,500 °C). Steel with a carbon content of 2.0% can be welded when orangish-yellow, between 1,700 °F (900 °C) and 2,000 °F (1,100 °C).

Bituminous is the coal-of-choice for the blacksmith. It is a soft, mid-grade, black coal. Mined from deeper mines than lignite, it burns much more cleanly.

Gas burns cleaner than a coal forge and is readily available. Some of the drawbacks to using gas is that it's noisier, and it makes the shop hotter in the summer time. Depending on the type of smithing that your doing gas is also generally considered more expensive than coal.

Is cold forging stronger?

Forging changes a metal workpiece through compression at either cold, warm, or hot temperatures. Cold forging improves the strength of the metal by hardening it at room temperature. Hot forging results in optimal yield strength, low hardness, and high ductility by hardening the metal at extremely high temperatures.

To practice cold forging prior to producing finished knives, he recommends intentionally cold forging steel until it cracks to have a better understanding of how much the steel can take. Cold reduction leads to an increase in hardness of the steel through an increase in dislocation density.

(a) Carbon-steel piping that has been heated to at least 1,650 °F (898 °C) for bending or other forming requires no subsequent heat treatment.

Coal typically burns the hottest of them all, so if you're looking to work with metals with high melting points, a coal solid fuel forge is ideal for you.

Temperatures need not be extremely high to begin to lower the properties of the steel. Some of the very hard wear plates found in industrial applications (near diamond hard) will begin to soften at 280° to 350°F.

Mild steel has to be annealed before cold forging and at interstage processes. Cold forging causes strain hardening in the materials, resulting in increases of 30–120% in tensile strength and 100–300% in yield strength values. There is a corresponding decrease in tensile ductility and impact properties.

What Is Cold Forging? Cold forging deforms metal below its recrystallization point – near to or at room temperature. A preferred forging method for softer metals (such as aluminum), cold forging is less expensive and has the ability to produced forged parts that require little or no finishing processes.

Therefore if you do not use flux you must raise the temperature enough to make the elements on the surface fluid. In order to take the mystery out of forge welding you must realize that blacksmiths flux may not be required, but it does, in most cases, make it easier.

No, the tank won't explode if it is shot. Fire needs oxygen to burn, and there isn't enough oxygen in the tank to fuel an explosion. The bullet is also not hot enough to ignite the propane. Propane has to be pressurized in order to become liquid.

Keep it in the shade.

While your tank should not be stored indoors, it should also not be stored in direct sunlight. On a hot sunny day, the temperature of a tank that's not properly stored could quickly go above 120°F. The hotter your tank gets, the greater the pressure will be inside the tank.

Can burning propane cause death?

Inhaling carbon monoxide can be very dangerous for health and may even cause death. Carbon monoxide is released when appliances and vehicles burn combustibles such as propane, wood and fuel oil.

Does propane expire? Another way you get peace of mind with propane delivery from Bottini Fuel is that propane doesn't have a shelf life or an expiration date. That's because propane doesn't go bad! Other fuel sources can degrade over time, like kerosene, diesel, heating oil and gasoline.

The freezing point of propane is -306.4°F degrees Fahrenheit. The coldest temperature recorded in Newburgh is -20˚F. So there's not much reason to be concerned about your propane freezing.

Unless temperatures are somewhere well below -40°F, your gas will not freeze solid in your gas tank or fuel lines. However, it can easily start to crystallize at extreme temperatures. Those gas crystals while get pulled out by the fuel filter, but that may lead to your fuel filter clogging.

A 100lb tank is about 80$ to refill for me and lasts around 16-18 hours of forging, so about $5 hour to run it.

On a multiple burner atmospheric gas forge using side arm burners what do you recommend the spacing to be between the burners ? A. I recommend the burners to be 3 1/2" to 4" on center and no more, this will insure that you get an even heat on your pieces of metal that you are heating.

If a first stage propane regulator is used, a second stage propane regulator must be installed downstream. In other words, a first stage propane regulator can't be installed independently in an LP Gas system. There must be a second stage propane regulator installed as well.

Internal Temperature: A campfire can reach internal temperatures of 1650°F (900°C) in the flames, known as the continuous flame region. Cooking Temperature: Above the flames (called the thermal plume region) where no flames are visible, you can expect temperatures of about 600°F (320°C).

Does Burning Wood Make it Stronger? When timber is heated within the flames of a fire, the grains of the timber are fused even tighter together, resulting in a stronger, more durable board.

This high-temperature, fast melting propane forge is designed to melt metals up to 2300°F. This forge can handle metals such as gold, silver, copper, aluminum, brass, bronze, tin, etc.

Can you use a BBQ as a forge?

A cheap barbecue makes a surprisingly effective forge. The tube is attached to a camp-bed inflator fan which pumps air through the charcoal to superheat it.

Step 1: Heat until yellow

Using your tongs, grasp the steel and heat it in a forge to the point where the color turns yellow (around 2,100 to 2,200 degrees Fahrenheit).

The forging process involved molding the knife at a critically high heat level (typically 900 - 2,000 degrees Fahrenheit) to improve its hardness.

Cherry Heat: 1,400 to 1,600 Degrees F

Bringing the heating temperature down further from orange, steel will take on a cherry color. When the steel's temperature falls in this range, it's much easier to upset lighter stock steel. “Trying to upset light steel at a higher heat is like pushing spaghetti,” Schantz says.

Blacksmiths cook the coal until most of the impurities are burned off. The result is co*ke, a fuel that is almost entirely carbon allowing us to reach temperature of 3,000 to 4,000 degrees Fahrenheit at the core of the fire! Fire this hot can quickly get the metal up to welding temperatures at about 2,500 degrees.

Gas forge can get as hot as 3000 degrees Fahrenheit. Wood forge and coal forge can operate within the temperature range of 1500-2500 degrees Fahrenheit.

Most importantly, your forge needs to be able to reach the right temperature to soften the metal, but not hot enough to melt it. The appropriate temperature for forging iron is 2500 degrees Fahrenheit or 1371 degrees Celsius.

Upwards of 2200 degrees, that is so hot you can't see it because your eyes can't deal with that bright an intensity. You need sunglasses. It's really very hot.

Preparing Wood

As you prepare the fuel for your forge, consider the amount of surface area of the wood. A large chunk of wood does not have as much exposure to oxygen as the same piece will when it is split smaller. The more surface area you have, the faster your wood will become charcoal and make a hot fire.

For example, if you want to work with metals that have particularly high melting points, you may want to choose the coal or solid fuel forge. These forges burn the hottest, at around 3,500 degrees Fahrenheit, followed by propane, charcoal, and wood.

How do I make my forge hotter?

- Use natural lump charcoal instead of charcoal briquettes. It costs more, but is really does burn a good deal hotter.

- If one hairdryer isn't enough, use TWO hairdryers! That or a wet-dry vac with the hose hooked into the exhaust port. That works pretty well.

- Osage orange, 32.9 BTUs per cord.

- Shagbark hickory, 27.7 BTUs per cord.

- Eastern hornbeam, 27.1 BTUs per cord.

- Black birch, 26.8 BTUs per cord.

- Black locust, 26.8 BTUs per cord.

- Blue beech, 26.8 BTUs per cord.

- Ironwood, 26.8 BTUs per cord.

- Bitternut hickory, 26.5 BTUs per cord.

Forging changes a metal workpiece through compression at either cold, warm, or hot temperatures. Cold forging improves the strength of the metal by hardening it at room temperature. Hot forging results in optimal yield strength, low hardness, and high ductility by hardening the metal at extremely high temperatures.

Both the ASM Metals Handbook and ASM's Forming and Forging Handbook state that "for stock up to 3 in. in diameter, the heating time per inch of section thickness should be no more than 5 minutes for low-carbon and mediumcarbon steels, or more than 6 minutes for low-alloy steels.